Slurry wall is a ground improvement technique that uses non-structural underground barriers to build cut-off walls to prevent the flow of water.

Presentation and key elements

What is slurry wall and why do we use it?

Soil-bentonite slurry walls are non-structural underground barriers. This technique is typically used to build cut-off walls to prevent the flow of water.

Due to this it is often used as an environmental remediation technique which limits the migration of contaminants from one site to another via natural water flow gradients.

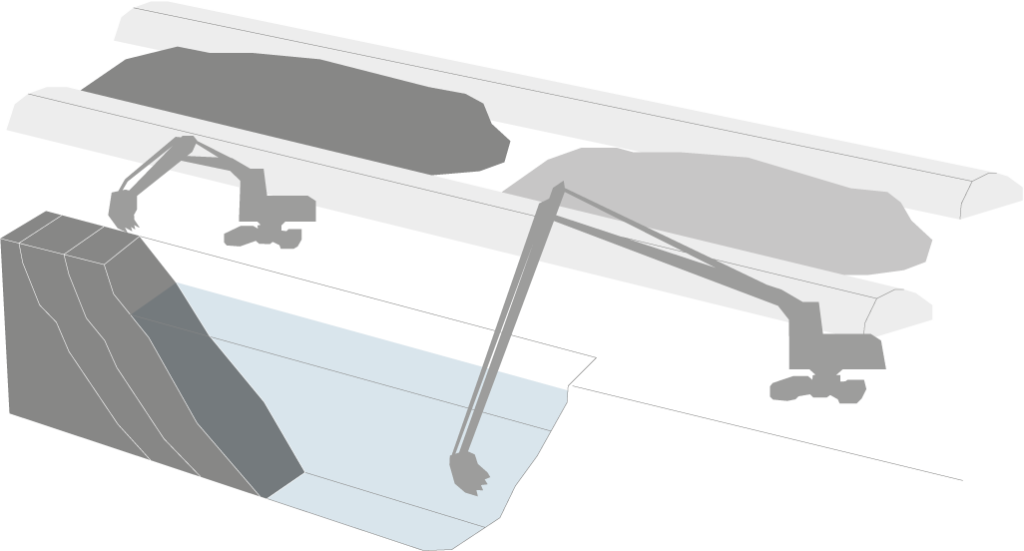

Basic principle of slurry wall

A trench is excavated whilst simultaneously the trench is kept full of a bentonite slurry in order to prevent the wall of the trench from collapsing / caving in. The excavated materials are blended onsite with a slurry made of bentonite and water with the typical addition of fines or aggregates. These are used to obtain a homogeneous, stable soil-bentonite slurry which is used to replace the soil bentonite slurry in the excavation.

The wall ultimately constructed possesses very low values of permeability. These values which are designed to be in line with the required hydraulic and permeability characteristics for the wall to act as a barrier to the flow of water.

Execution of slurry wall

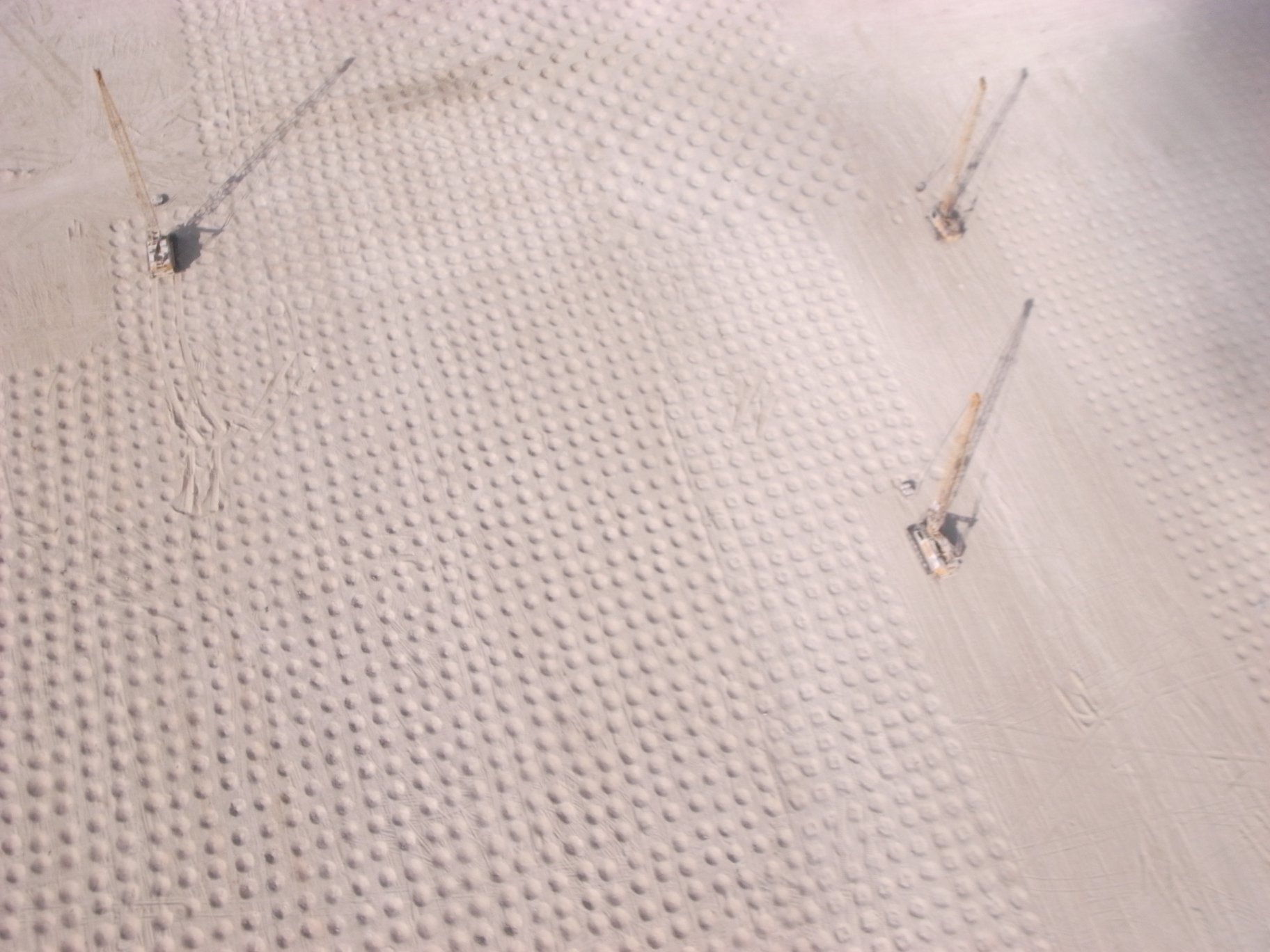

The Slurry Wall can be executed using several different technique’s dependant on the design depth of the wall. Long boom excavators can be used for trenches with a depth of up to 20 meters where high production rates (about 200 m² per shift) can be achieved as the excavation of the trench is performed using backhoes. For depths exceeding 20 meters equipment such as grabs can be used where depths of up to 45m can be reached.

Whilst the trench is excavated a bentonite slurry is introduced to stabilise the side walls. Soil, bentonite, water, cement (if required) are mixed on site using a bulldozer in a designated area or on the ground to obtain an impervious mixture. After blending, the trench is backfilled through gravity flow with the soil bentonite slurry which replaces the bentonite slurry used to stabilize the trench. The backfilling is performed in phases with a slope of roughly 6H:1V. The length of excavation is therefore 6 times longer than the depth of the slurry wall.

Thanks to the re-use of excavated materials for the wall slurry, very little spoils are generated, which considerably reduces the requirement for disposal of spoils.