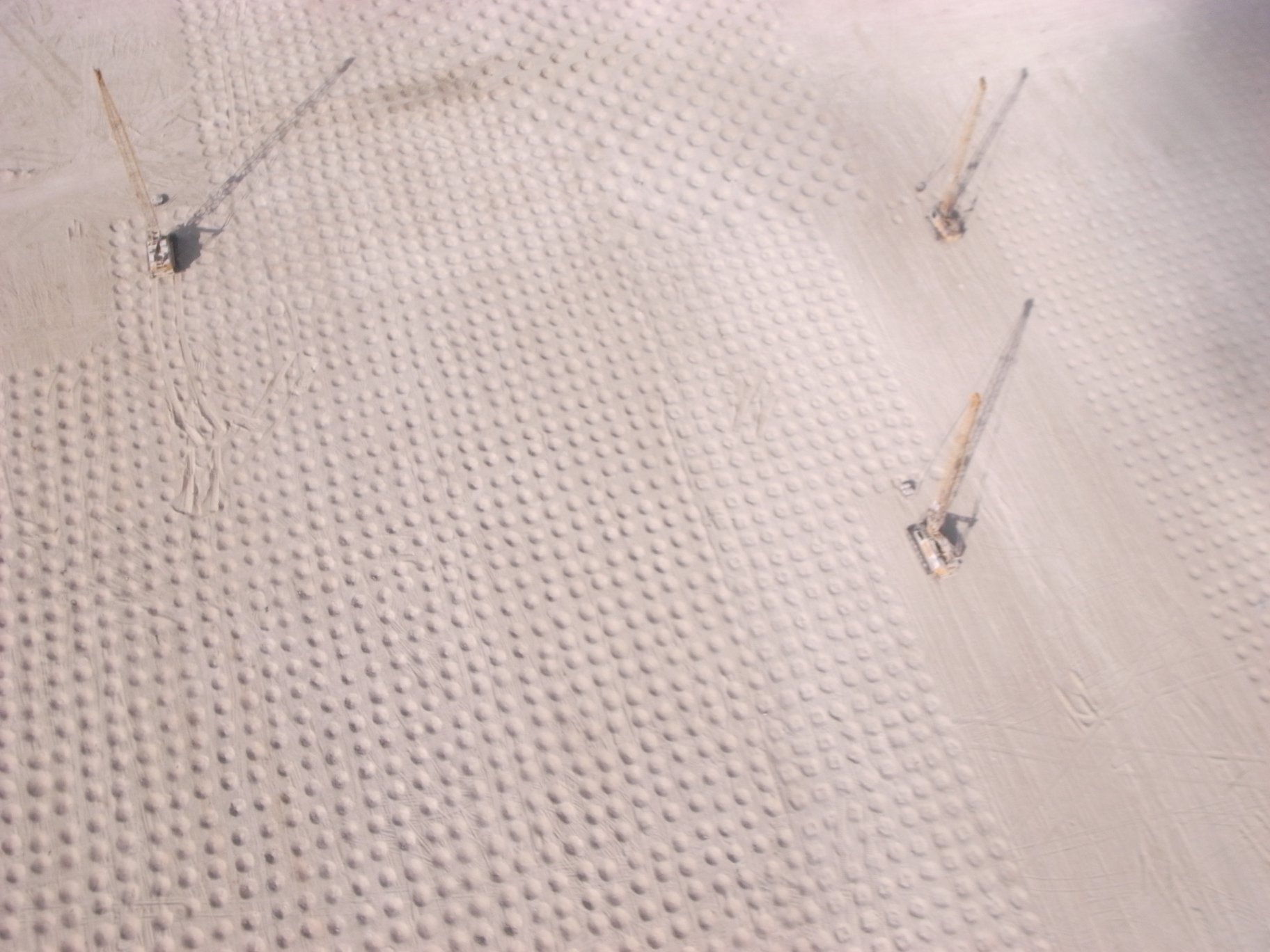

Soil improvement and reinforcement by dynamic compaction

The municipality of Trélazé, on the outskirts of Angers, was a major centre for slate-quarrying throughout its long industrial history, from the middle of the 16th century until the eventual closure of the last slate quarries in March 2014. Menard has been working between mid April to beginning of june 2022 to improve the soil on this industrial wasteland and give it a new lease of life with the construction of a tertiary and logistics business park.

New life for an industrial wasteland

A rich history of slate quarrying

The site we are working on is a former slate quarry from which clay slate was extracted for almost six centuries. Slate quarrying at the site dates back to the 15th century, with evidence of industrial developments throughout the ages.

At its peak in the early 1900s, there were more than 6,000 quarrymen in the Bassin de l’Anjou, extracting around 250,000 tonnes of slate each year. This rich industrial history can still be seen today on the roofs of many buildings (churches, castles, etc.) along the Loire valley (in Tours, Amboise, Blois, Orléans, etc.) as well as in Paris and Normandy, where slate could be transported via the canals linking the Loire to the Seine.

The site is now located in the heart of an urban landscape. The quarry, like other sites, has become an industrial wasteland that the municipality is gradually rehabilitating to create new districts, cultural and sports facilities and tertiary areas.

As part of this redevelopment, Menard was appointed to improve the soil of an 11 ha plot between April and June 2022.

The soil improvement solution

Geotechnical context

Shale production and processing workshops, along with storage buildings and changing rooms, were still present on the site until 2021. Demolition work exposed a large network of shallow tunnels formerly used by the quarry carts.

In preparation for the construction of new buildings to create a tertiary and logistics business park, the project designers therefore had to come up with solutions to adapt to the constraints imposed by the site’s industrial past:

- Existence of reclaimed land, where the surface comprises slate shale fragments between 0.4m and 5.5m deep;

- Identification of layers of clayey sand with loosely compacted sandy clay covering the schist substratum with a highly variable level of alteration;reclaimed land, where the surface comprises slate shale fragments between 0.4m and 5.5m deep;

- Major variation in sedimentary facies within the plot, from outcrops of compact schist to more or less altered schist with a significant covering of clayey-sand deposits;

- Remnants of buildings (old tunnels, partially destroyed and filled in), some remains of leftover foundations despite demolition.

The real-estate infrastructure project

The planned real-estate complex includes:

- A 12,500 sq. m logistics storage building;

- A 1,700 sq. m workshop and office building;

- A 900 sq. m training building;

- A 600 sq. m washing and pump building;

- A 4,700 sq. m outdoor storage;

- Concrete areas for truck storage covering 12,700 sq. m.

The foundation solution adapted to the soil

At Menard, the study of a soil reinforcement and improvement project always begins with an in-depth study in order to offer each site the solution best suited to its geotechnical constraints, while guaranteeing the best cost/performance ratio.

In this case, studies indicated two soil improvement solutions to improve the soil: rigid inclusions and dynamic compaction.

An in-depth analysis of the data identified certain risks which steered the final choice:

- The likelihood of uncovering old tunnels missed off the survey argued in favour of compaction, as this technique massively simplifies purging and backfilling operations, eliminating the need for pre-drilling in the case of inclusions;

- The difficulty of precisely dimensioning the concrete inclusions, due to the potential presence of cavities or complete voids in the backfill also indicated the need for dynamic compaction.

Dynamic compaction presents several advantages for this worksite:

- The conventional approach is possible and covers all identified contingencies;

- The remnants, voids in the backfill, blocks or other obstacles do not present a risk to the reliability of the foundations or teams’ safety;

- The dynamic compaction technique is easy to adapt according to the heights of the soil to be reinforced, as the depth of the bedrock surface varies considerably across the site;

- Dynamic compaction is a technique with one of the lowest carbon emissions. For this worksite, the adopted solution has a quarter of the CO2 impact of the inclusions solution, including emissions associated with the transport of personnel, equipment and materials.

Dynamic compaction